Patents

Right from its inception, the Trevi Group has distinguished itself for its innovation capacity in the field to which it belongs, by developing concrete solutions aiming at meeting actual operational needs. For this purpose and in order to protect the intellectual property of the inventions conceived, Soilmec has always promoted an intense patenting activity.

The first patent application submitted on behalf of Soilmec dates back to 1983; since then, 97 applications have been filed to protect the same number of inventions conceived by the company’s engineers. As of today, Soilmec holds patents granted or under concession for 76 of said inventions, while the patents of the remaining ones have been obtained but have now reached their natural expiry.

Soilmec Patents

1983 Telescopic Cab

Self-propelled drilling rig with telescopic moving cab on RTA-S © Davide Trevisani

1983 Crane lifting frame

Self-propelled drilling rig with rear lifting frame for crane attachment © Davide Trevisani

1983 Pivoting counterweight

Self-propelled drilling rig with pivoting counterweight © Davide Trevisani

1985 Ecomar

Weed harvester © Davide Trevisani

1985 Ecomar

Weed harvesting boat equipped with belt conveyors and containers © Davide Trevisani

1988 CLS control device

Control device for concrete injection in CFA with buffer tanks © Marco Pedrelli

1989 Parallelogram

Drilling rigs with parallel translating linkage © Davide Trevisani

1990 Trevipark

Automated multi-storey parking system with car lifts © Davide Trevisani

1990 SR cased piles

Four-bar linkage machine with Cardan coupling and screwed joints for casings © Davide Trevisani

1992 DMS

Drilling parameters’ automatic control system © Davide Trevisani

1993 Fall-prevention safety device

Rotary cradle fall-prevention system through eccentric elements © Davide Trevisani

1994 ‘Pirucca’

Eccentric shaft compaction tool and Method © Marco Pedrelli

1994 CSP

Equipment for cased CFA drilling combined with long auger extension, and Method © Davide Trevisani

1995 Gravity cleaner

Continuous flight auger cleaner with gravity scraping blade © Davide Trevisani

1996 Shoe grab

Jack-driven hinged shoes © Davide Trevisani

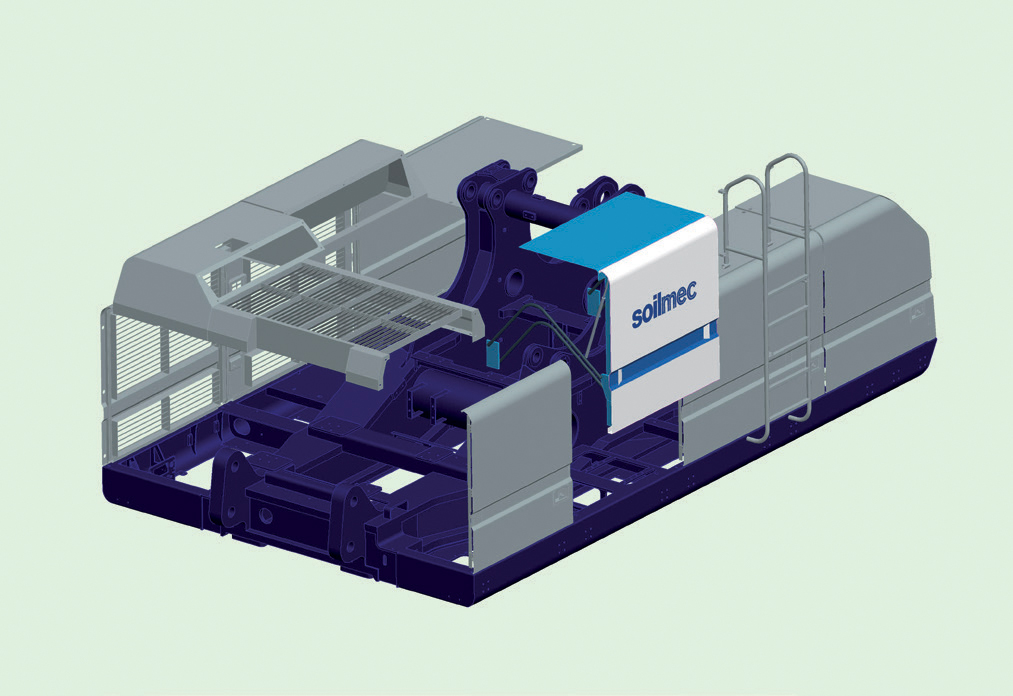

1996 Crawler carrier

Crawler carrier with telescopic, removable track roller frames © Bruno Bettini

1997 Rotograb

Grab with motorization between guide bar and body © Giorgio Rivalta

1997 Grab

Automatic centring of guide shoes with opposite springs © Davide Trevisani

1997 Trevipark

New wheelbase measuring system and centring and lifting devices on carts, and Method © Luciano Agostini – Giorgio Rivalta

1998 Auger tip

Double-body tool with passage for cuttings and auger cap for casting © Marco Pedrelli

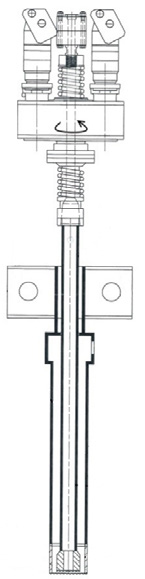

2009 TCT-S

Screw displacement device with mobile tooth © Alessandro Ditillo

2008 TJ-Idle

Turbojet blind boring tool © Ezio Biserna

2008 Hydromill

Gravity swivel joint for hydromill © Alessandro Ditillo

2008 ETJ

Enhanced monitor with selecting valve for using single-passage jet rods © Maurizio Siepi – Alessandro Ditillo

2009 Elliptical Jet

Enhanced elliptical system for increased depth © Maurizio Siepi – Alessandro Ditillo

2009 Stone columns – BFS

Device with automatic gravel discharge © Alessandro Ditillo

2009 Safety systems

Mechanical arm for drilling emergencies © Alessandro Ditillo

2009 Rod carousel

Mobile driving head © Fabrizio Macori

2009 TCT-180

Double body displacement tool © Stefano Massari

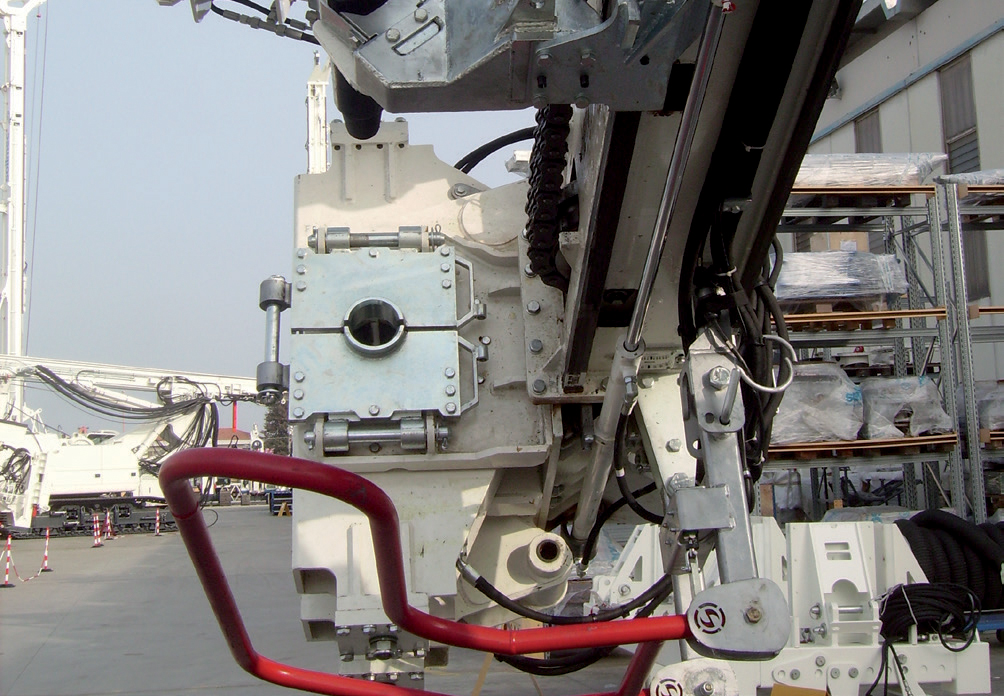

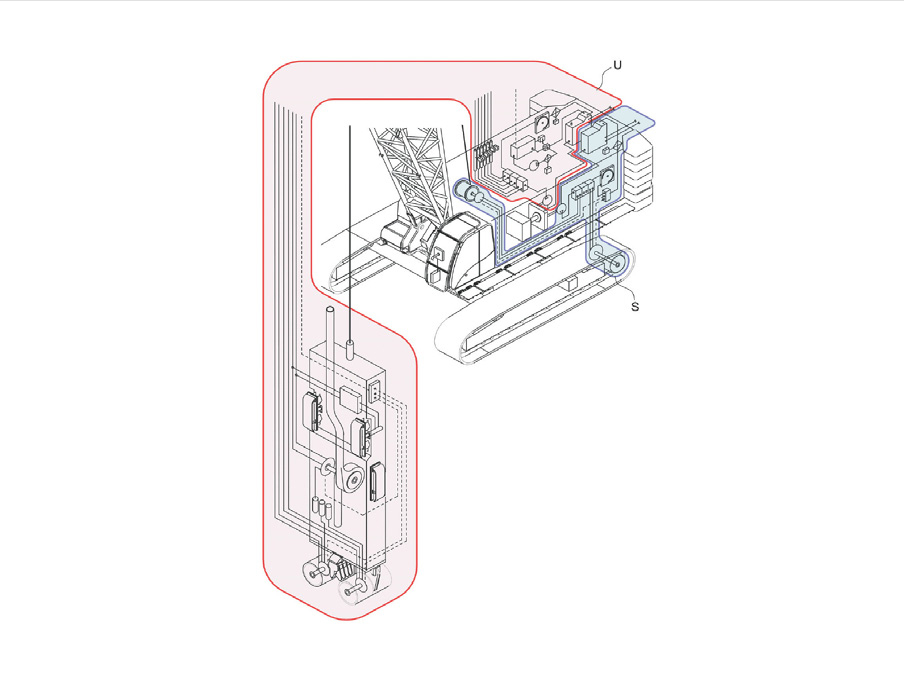

2008 SPS

Secant pile execution equipment with down the hole rotary head and reverse circulation © Alessandro Ditillo – Maurizio Siepi

2009 Hydromill

3-Dimensional Trench Profiler © Maurizio Siepi – Alessandro Ditillo

2009 TJ & DP

Multifunction rod © Ezio Biserna

2009 TJ TKTJ

Turbojet telescopic sleeve © Ezio Biserna

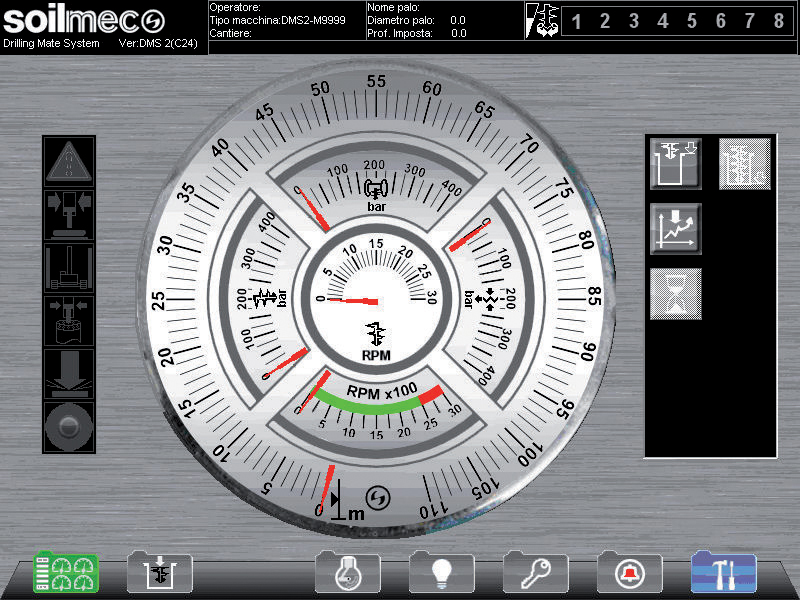

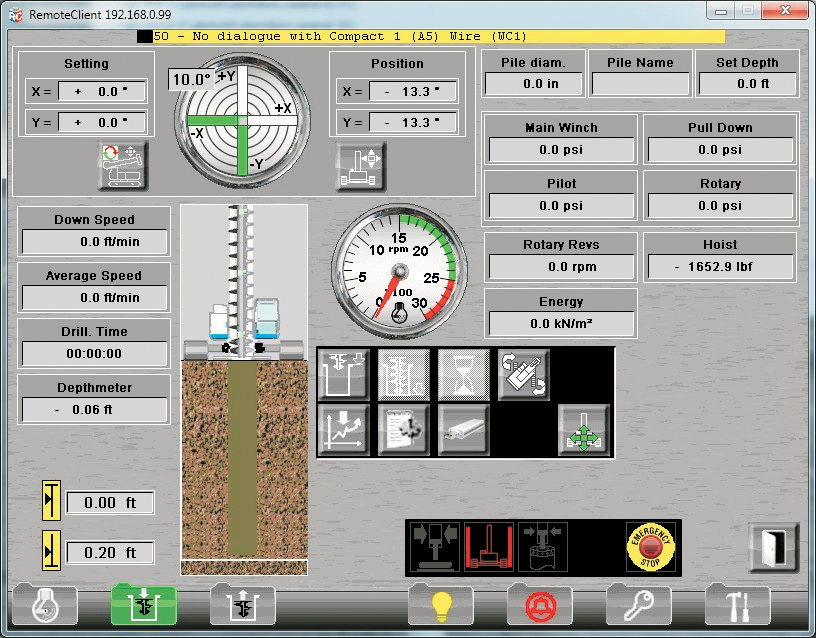

2009 DMS-2

Redundant control system for rig and drilling parameters © Pietro Fontana – Alberto Antonelli

2009 Safety device

Sylenced opening and sliding hood © Alessandro Ditillo – Stefano Massari

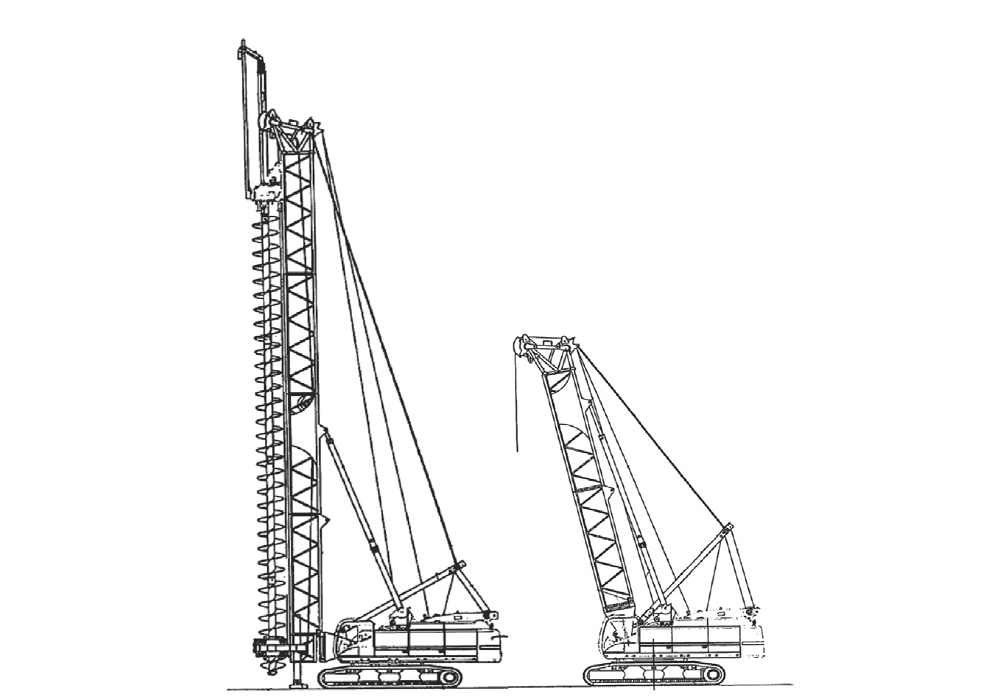

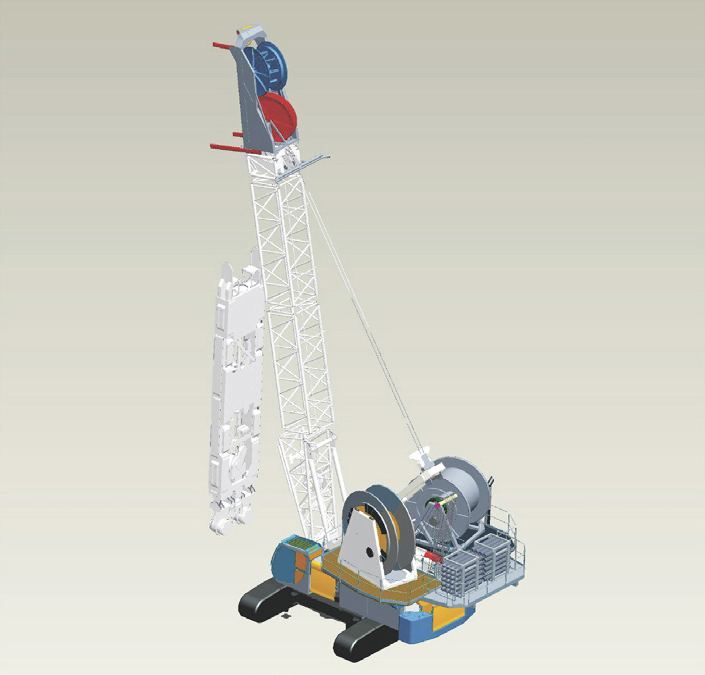

2009 Convertible crane

Convertible crane in drilling rig © Alessandro Ditillo – Stefano Massari

2009 LDP hybrid crowd system

Quick push, step by step crowd system © Ezio Biserna

2001 RCDS

R-930 RCDS with removable counterweights and reverse circulation system © Marco Pedrelli

2007 Hydromill

Tiger version hose drums (special head and hose wheels on lattice boom) © Gianluca Braghittoni

2007 Twin loader

Loader for drilling rods and casings with independent double rotary stroke © Patrizio Puntel

2007 Lifting device

Magnetic loading system for jet rods © Alessandro Ditillo

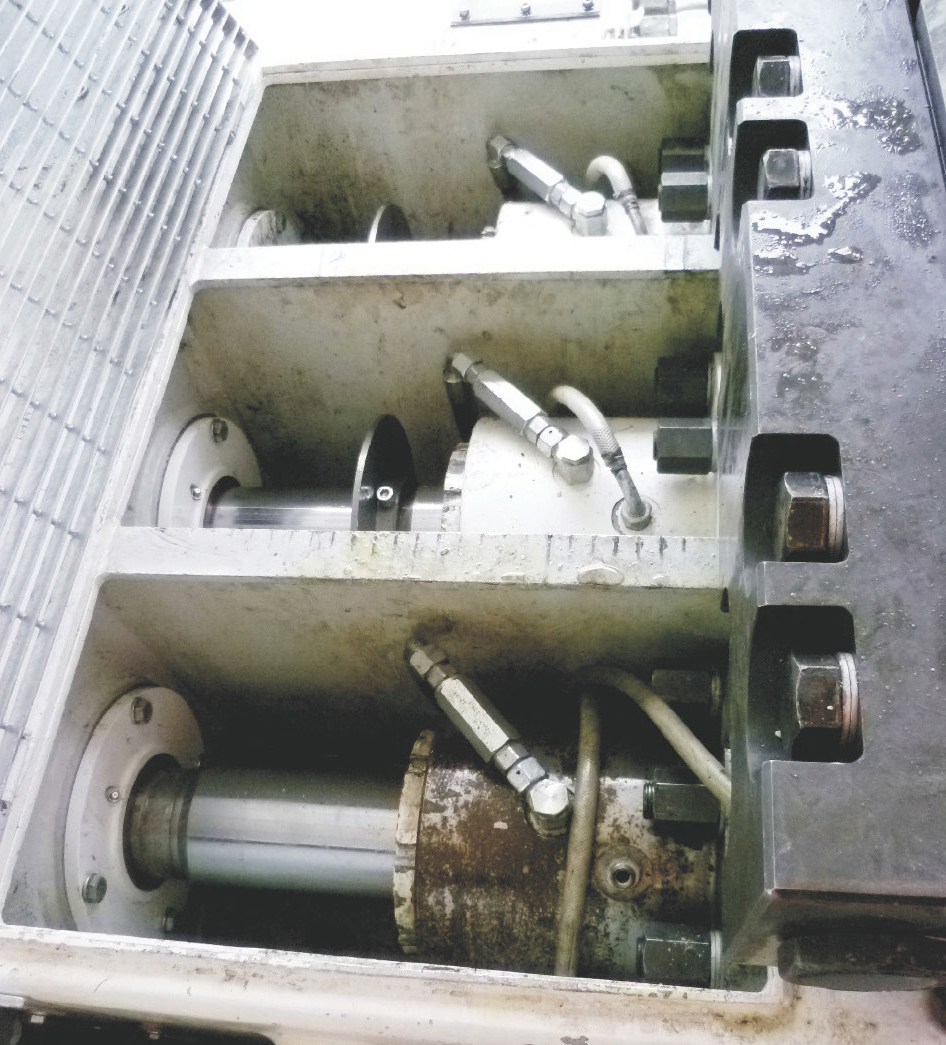

2007 Hydromill

Mud pump © Gianluca Braghittoni

2006 SC-100/120

Crane with self-erecting triangular support for LDP drilling © Marco Vocale – Marco Pedrelli

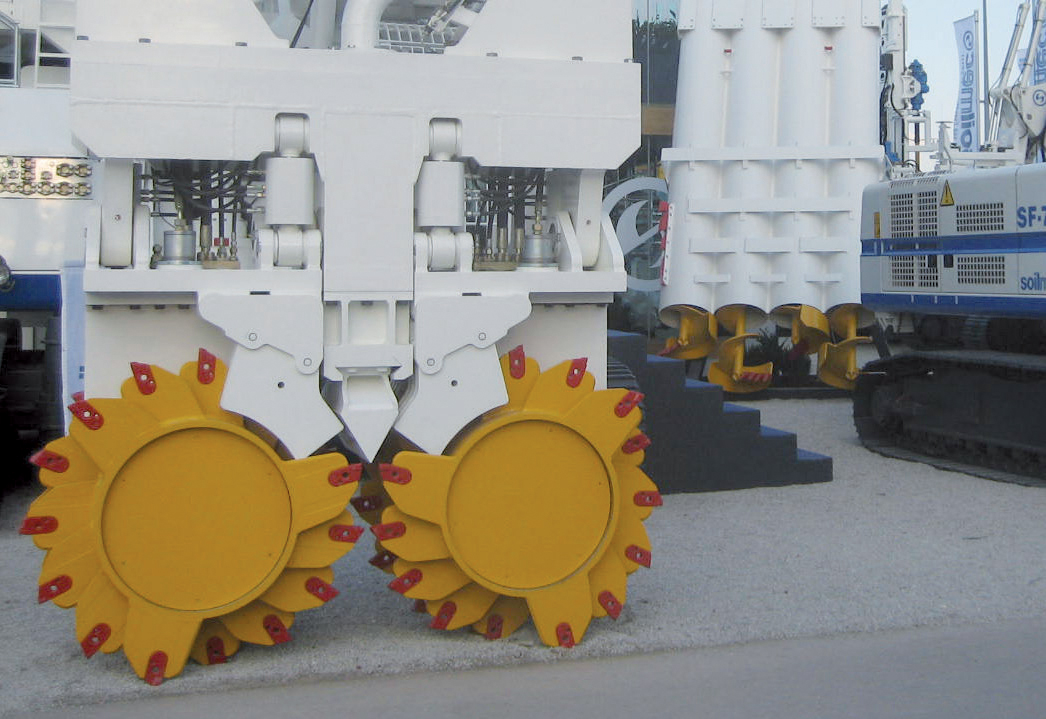

2006 Hydromill

Milling drums with independent tilting for verticality control © Alessandro Bertero – Giovanni Casadei

2006 Vibro-Jet

Vibro-drilling and vibro-jet grouting © Alessandro Ditillo

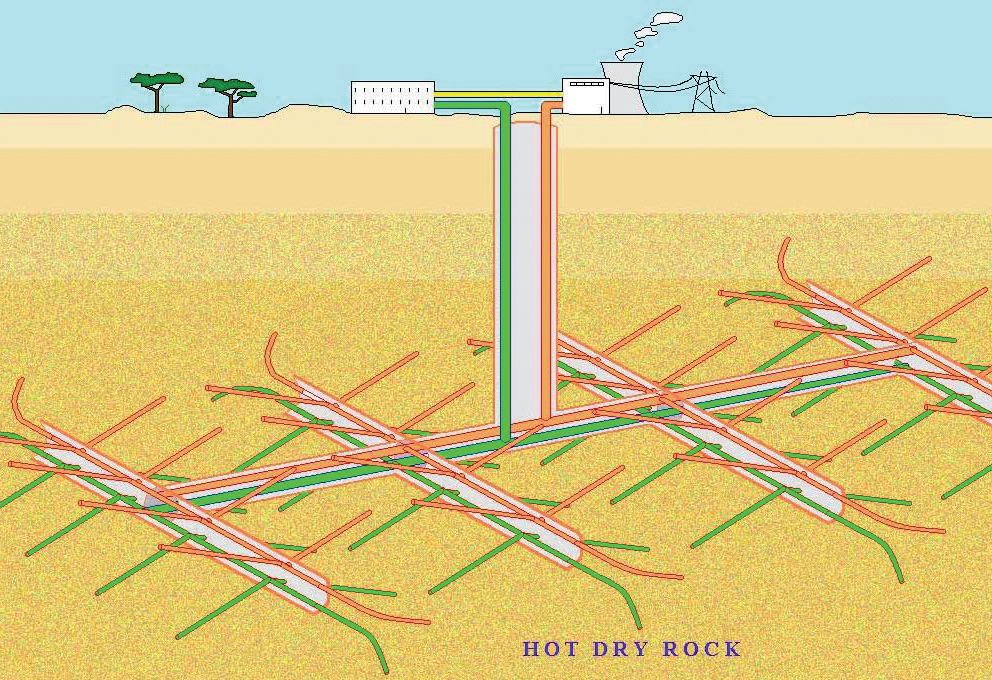

2006 Geothermics

Coaxial probes for deep geothermics, and Method © Davide Trevisani

2005 TCT

Traction compaction tool © Marco Pedrelli

2005 Hot dry rock

Deep geothermics, and Method © Davide Trevisani

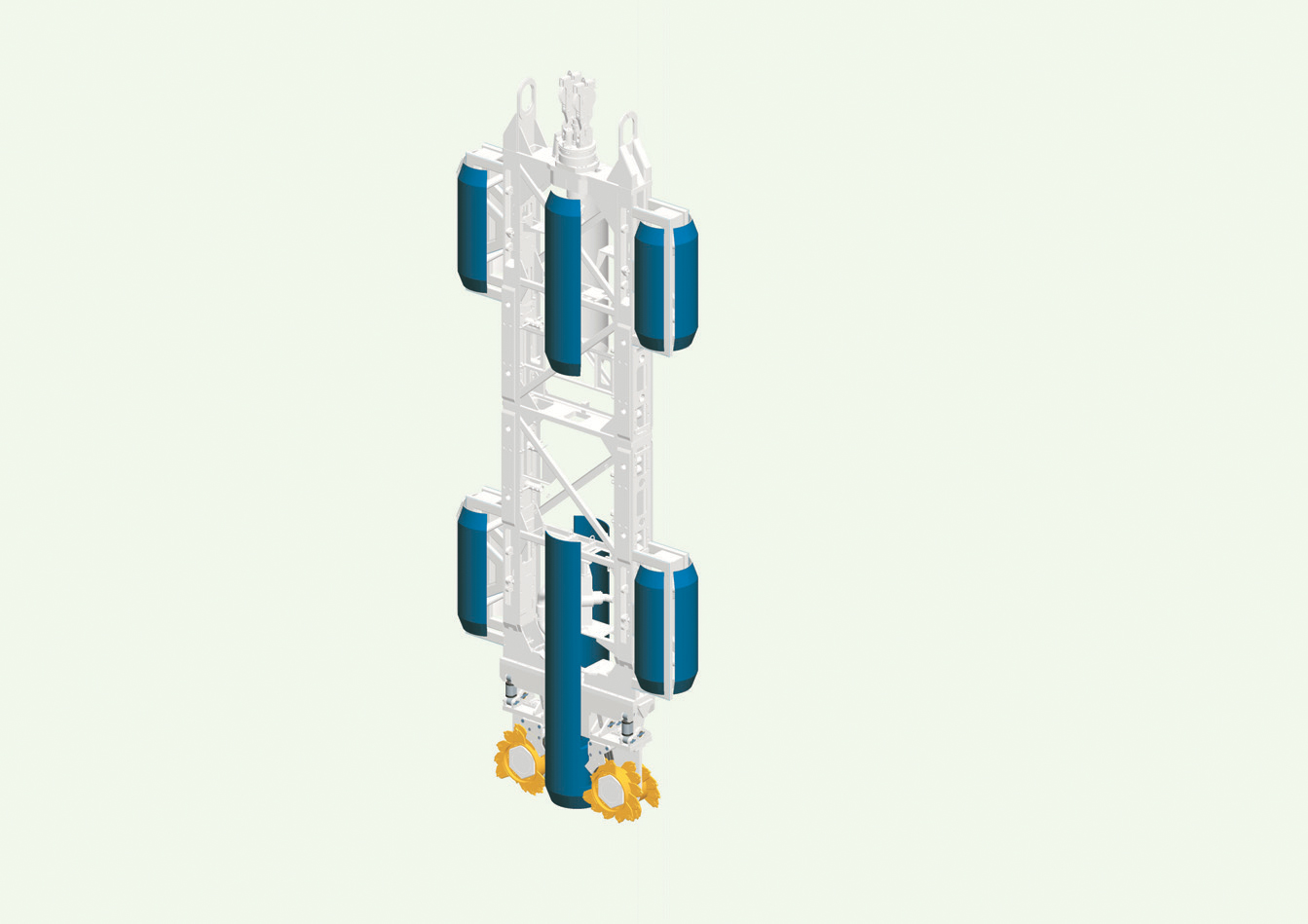

2005 Arapuni system

Equipment for secant piles executed by reverse circulation, and Method © Ezio Biserna – Maurizio Siepi

2005 Grab direction control

Grab excavation direction control with ropes © Davide Trevisani

2005 Multi mix

Mechanical mixing by means of augers for rectangular diaphragm walls, and Method © Davide Trevisani

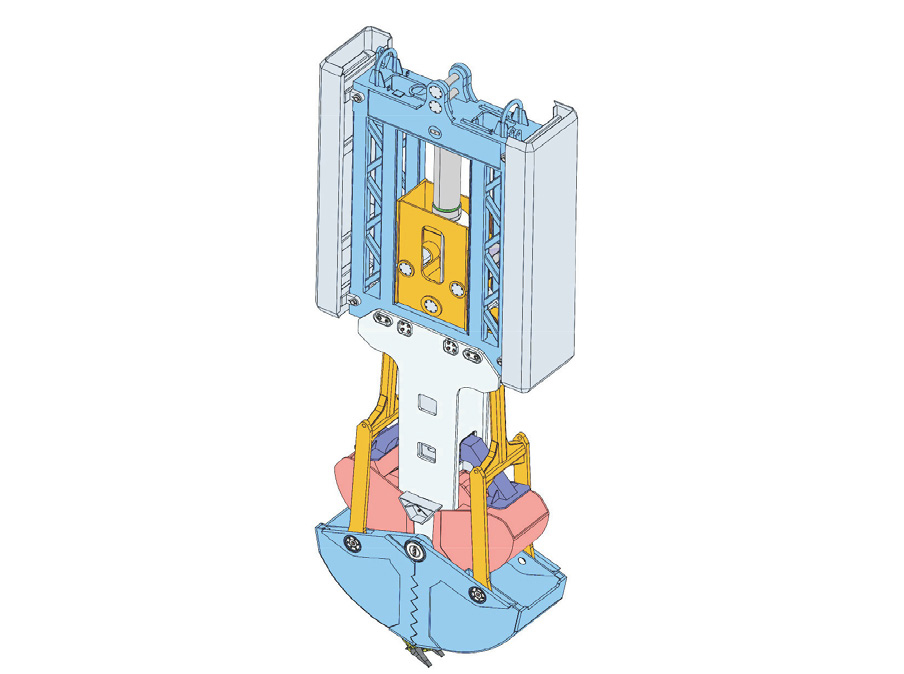

2004 Beli

Auger grab for diaphragm walls © Davide Trevisani – Marco Pedrelli

2004 CFA

Telescopic auger extension, and Method © Luciano Agostini – Bruno Bettini

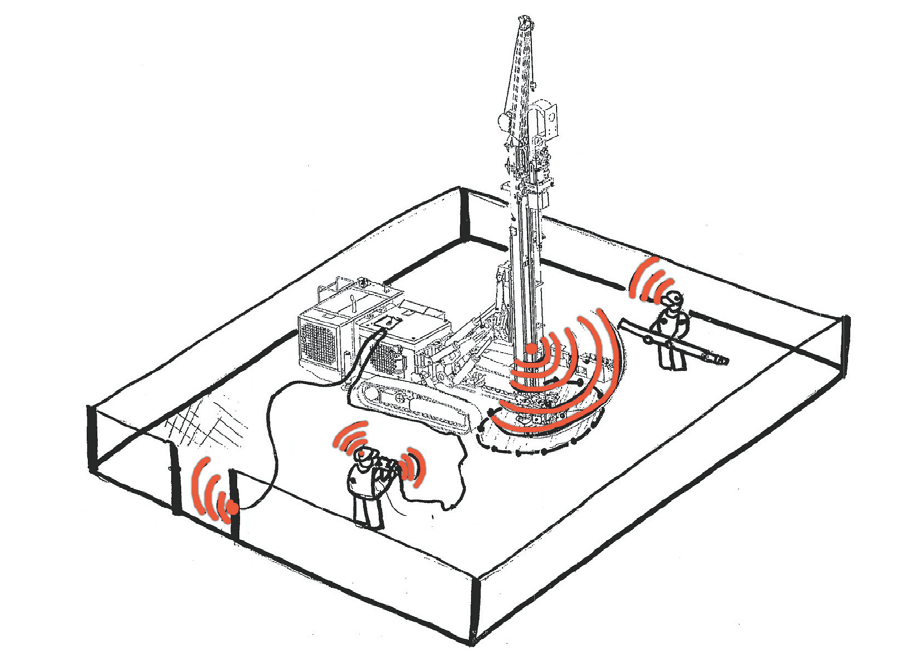

2014 Microdrilling-Safety

Portable sensor device and barrier to access © Alessandro Ditillo – Pietro Fontana

2011 LDP

Hydraulic motor with tangential piston for rotary © Alessandro Brevaglieri

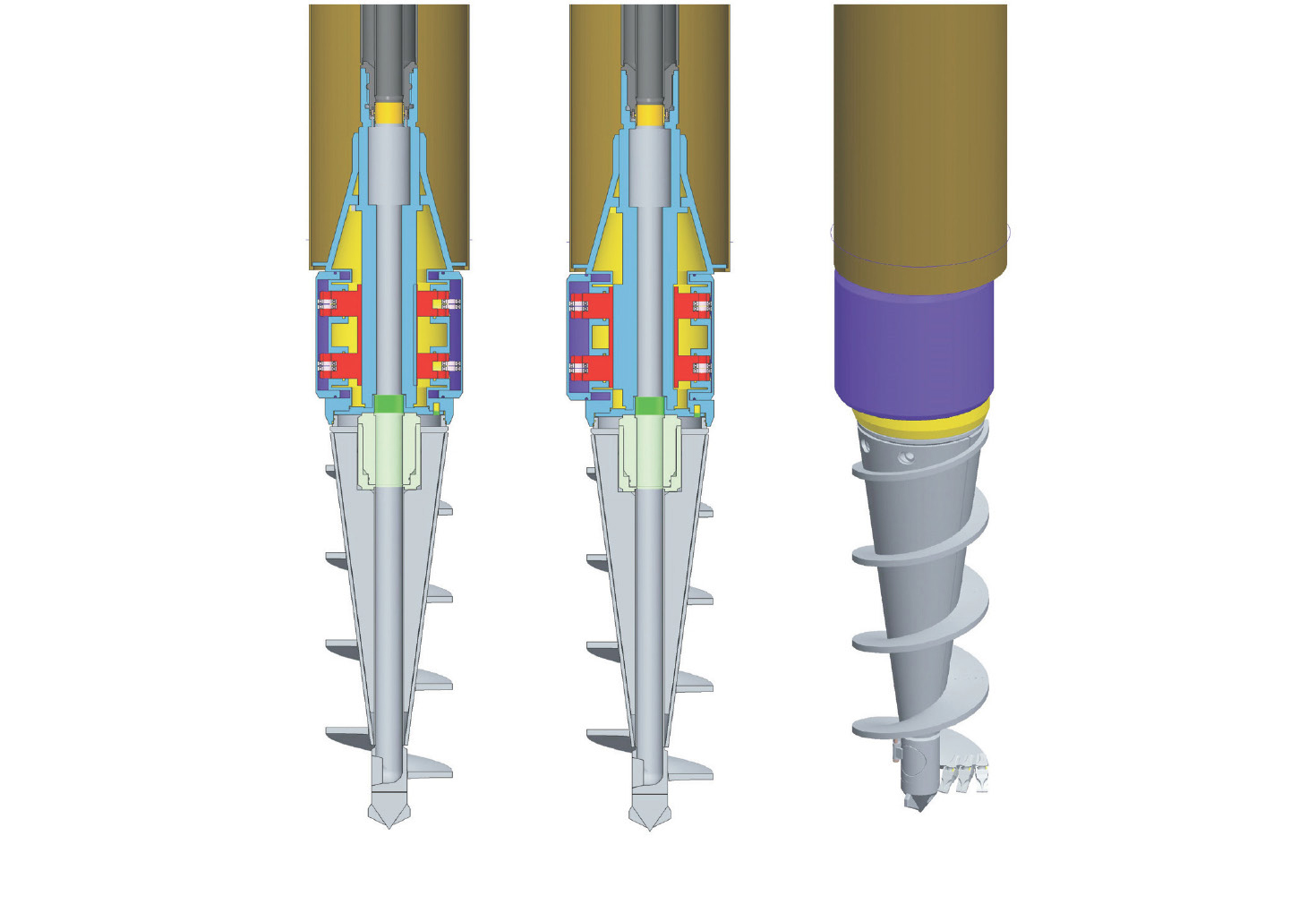

2012 CSP

Eccentric helical drill bit for CSP © Ezio Biserna – Daniele Vanni

2012 LDP

Kelly winch synchronized with the mast lifting movement © Massimo Morellini – Bruno Bettini

2012 Engine

Machine with dual-fuel engine and additional tank for gaseous fuel © Paolo Tiezzi – Alessandro Ditillo

2012 CFA

Openable auger cleaner © Alessandro Ditillo – Claudio Benzi

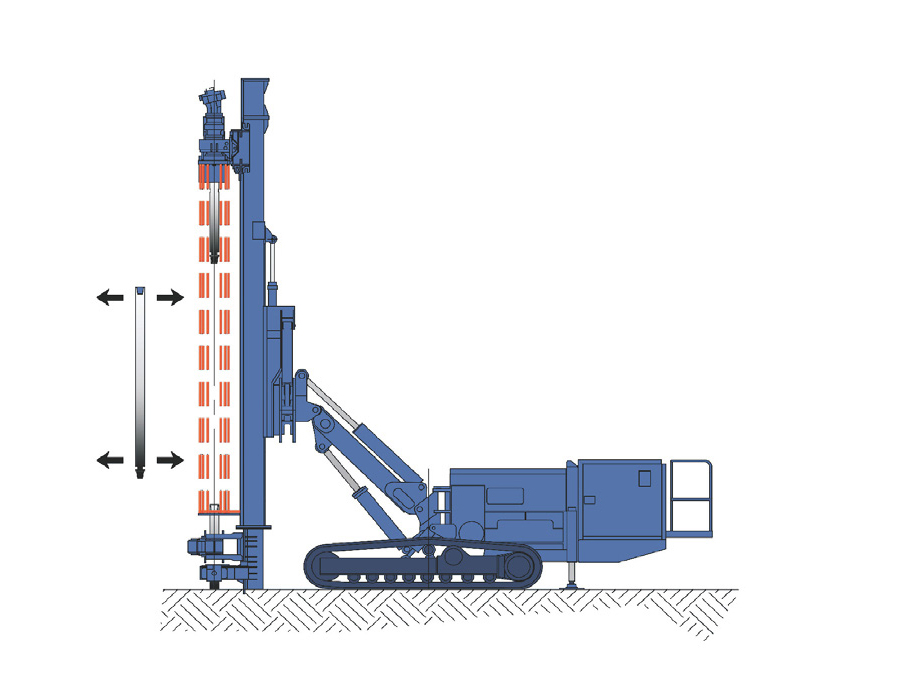

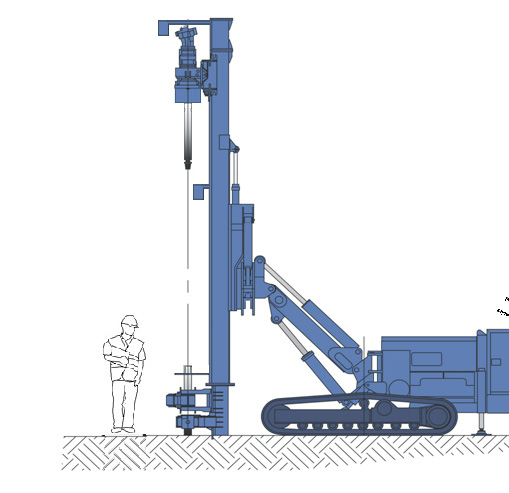

2013 Microdrilling

Multi-purpose mechanism for arm and mast movement © Stefano Massari – Alessandro Ditillo

2013 Diaphragms

High capacity bucket © Stefano Trevisani – Ezio Biserna – Jasmin Curic – Marco Pedrelli

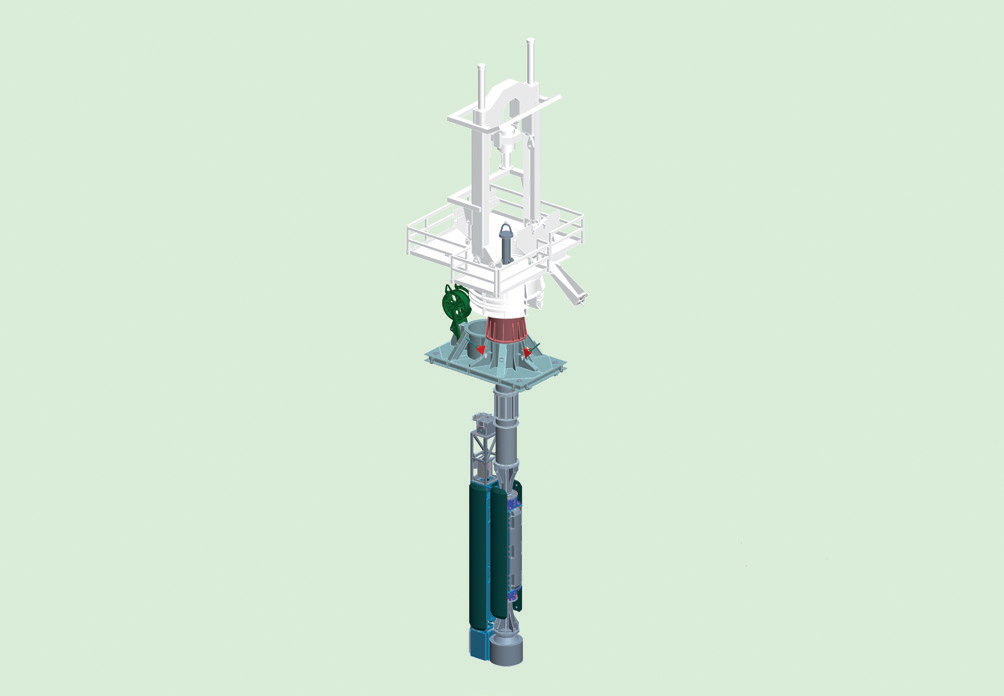

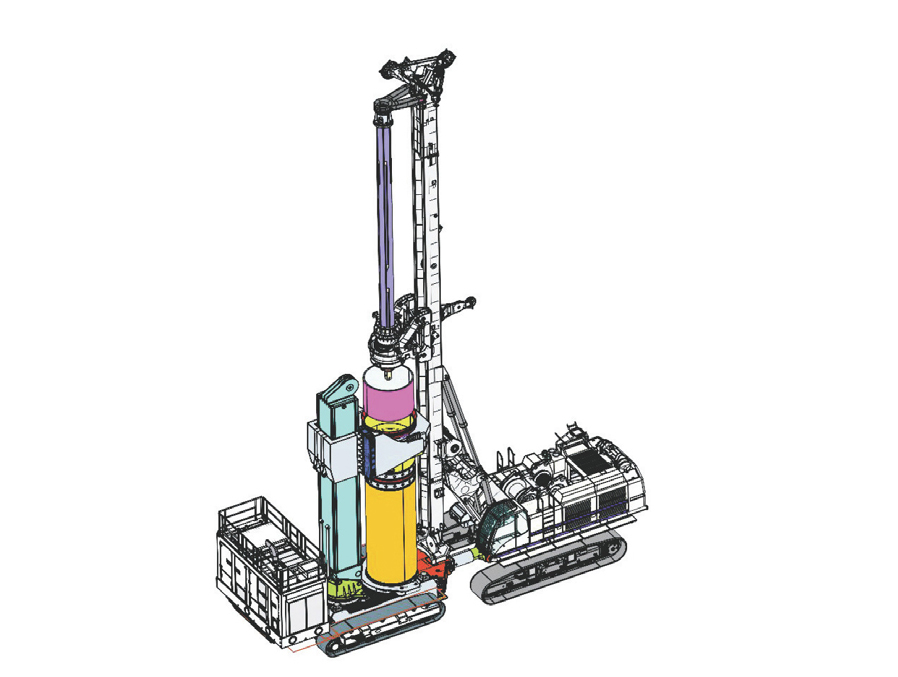

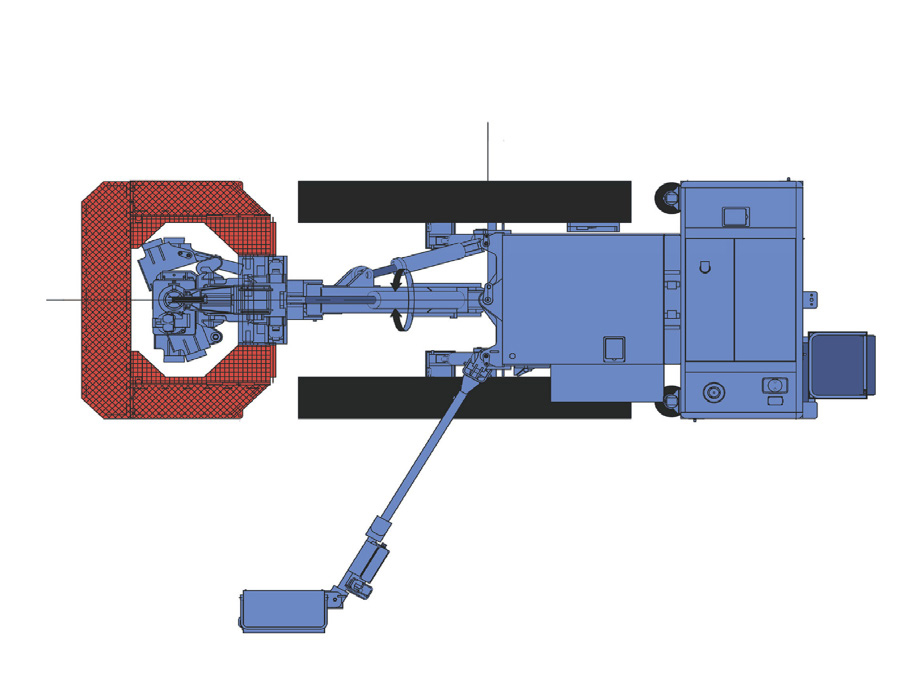

2014 CSP

Machine for great-depth and large diameter CSP © Alessandro Ditillo – Stefano Massari – Alessandro Giunchedi – Marco Casadei – Jasmin Curic

2014 Hydraulic Circuits

Machine with separated hydraulic circuits © Valentino Ciccottelli

2014 Microdrilling-Safety

Protective shield and sensitive device © Alessandro Ditillo

2011 Energy

Energy recovery system with ORC device © Massimo Morellini – Alessandro Ditillo – Marco Casadei

2014 Microdrilling-Safety

Telescopic guided guard © Alessandro Ditillo

2014 Microdrilling-Safety

Load-sensible platform © Pietro Fontana

2015 CFA – CSP

Device for the handling and mutual assembly of auger segments © Ezio Biserna – Danilo Fusaroli – Francesco Mantovani

2015 Microdrilling

Boring head and casing ring cooperating in rotation © Patrizio Puntel

2015 Microdrilling-Safety

System to detect a risk condition in a region close to a drilling machine © Pierandrea Zanolini – Devis Luison – Luca Agostini

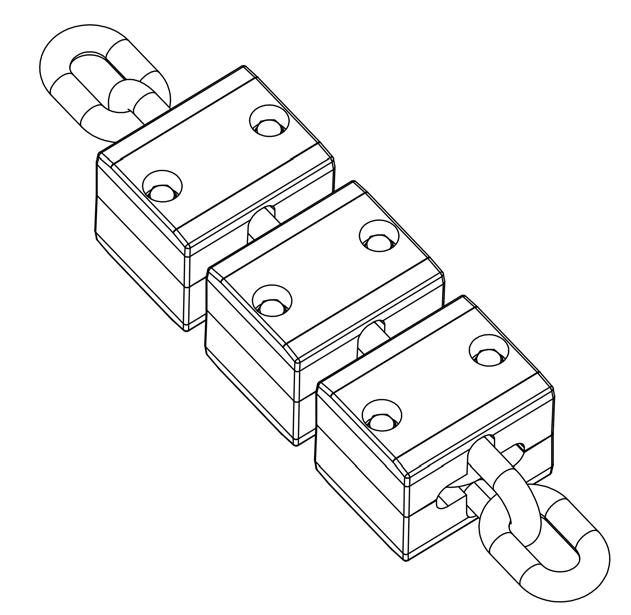

2016 Hydromill

Hose-chain with internal ring-chain © Armando Mirco Raffuzzi – Franco Visani

2016 LDP

Anti-slack system for kelly rope © Alessio Zanichelli

2017 Hydromill

Trench-profiler and I.M.U. for deep excavation © Armando Mirco Raffuzzi – Pietro Fontana – Ivano Guerra

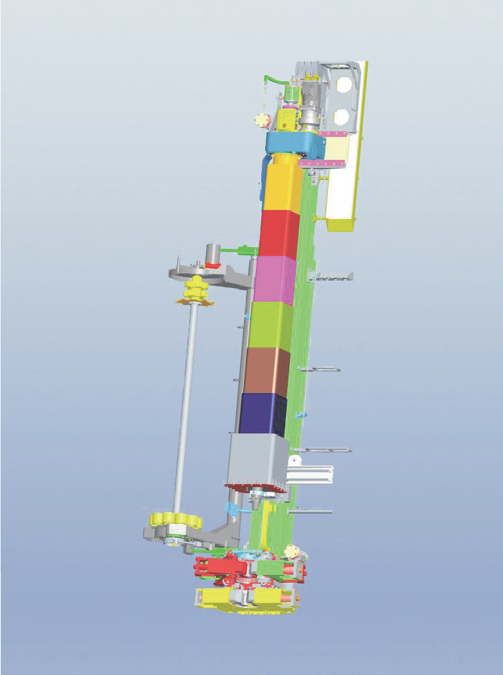

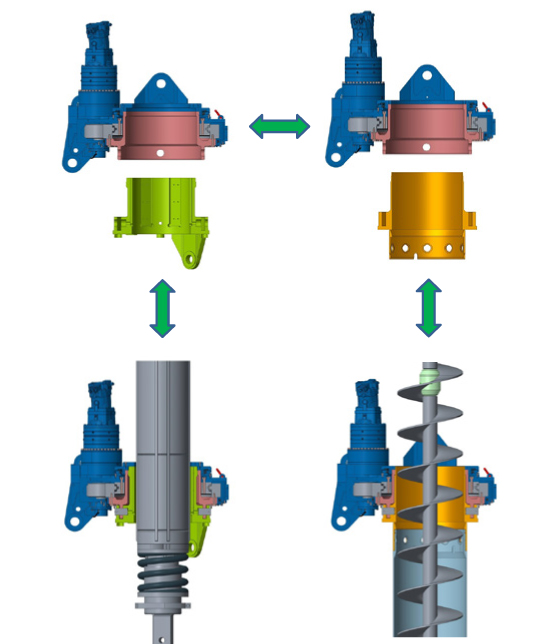

2017 LDP – CSP

Quick conversion system for LDP-CSP configuration © Alessandro Ditillo – Ezio Biserna

2011 LDP

Indipendent circuit for casing locking device © Luciano Agostini

2010 Ergonomics

Capacitive joystick © Ivano Guerra – Pietro Fontana

2010 LHR

Kelly partially passing through rotary head © Luciano Agostini

2010 DP

CDP – Cased Displacement Piles © Jasmin Curic – Paolo Cavalcoli – Ezio Biserna

2010 Hydromill

Guided hydromill trench by a central hole © Davide Trevisani – Stefano Trevisani – Maurizio Siepi – Carlo Crippa

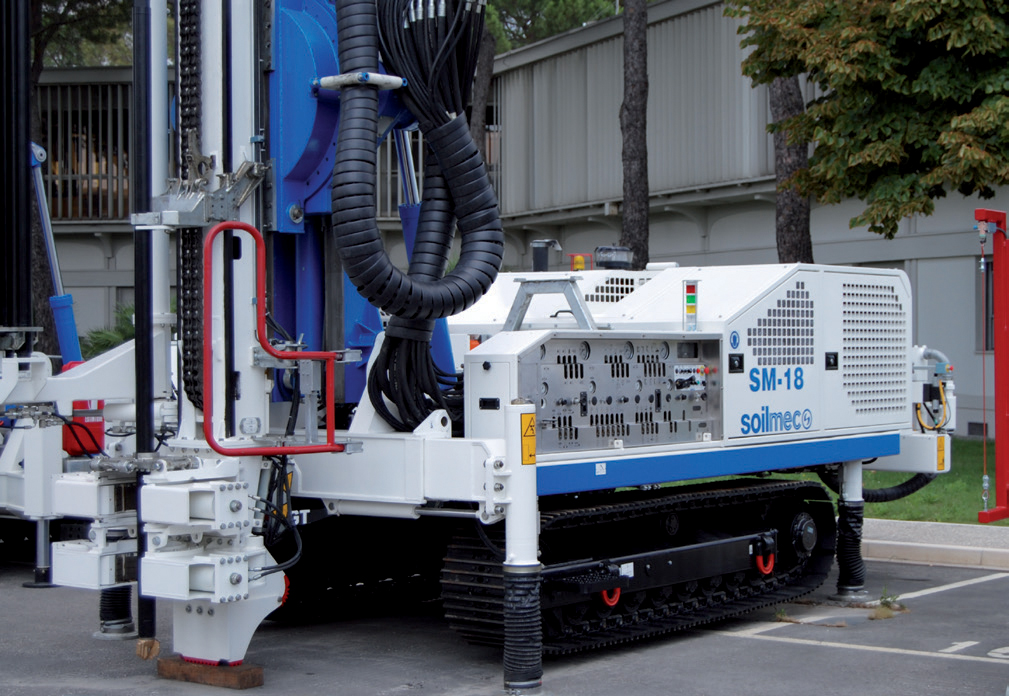

2010 SR – SF – SM

Torque misure device © Simone Trevisani – Marco Casadei – Alessandro Ditillo

2010 Safety

Collapsible and foldable parapet © Alessandro Ditillo – Stefano Massari

2010 Jet Grouting

Snake-jet high efficiency monitor © Ezio Biserna

2010 CAP – CSP

Specific drilling energy © Alessandro Ditillo

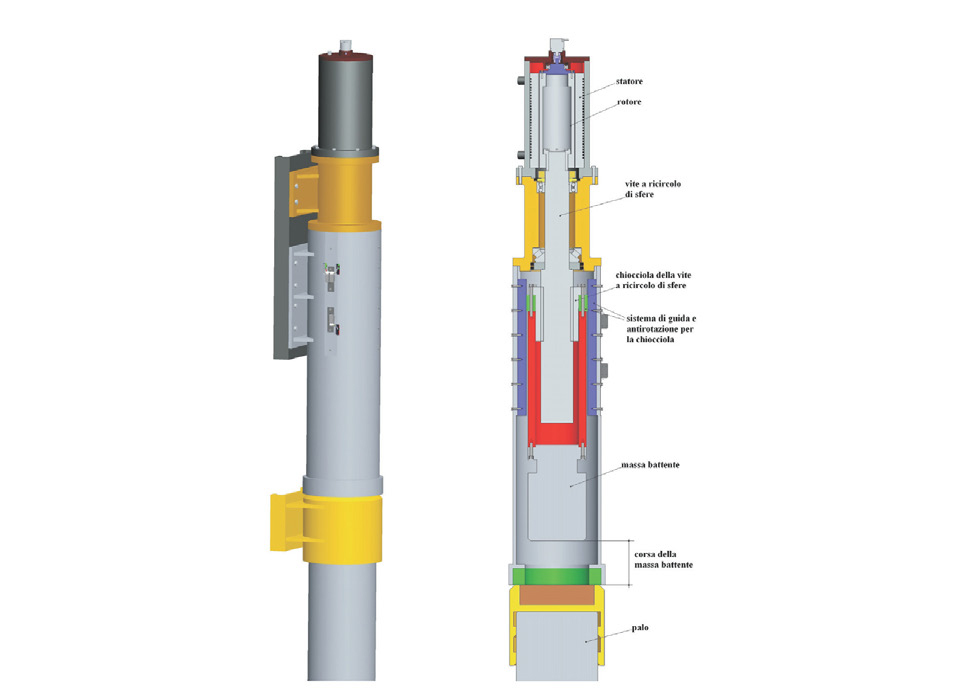

2010 Driven piles

Electric hammer with permanent magnet technology © Marco Casadei

2011 RCDS

Reverse circulation road manipulator © Marco Casadei – Ezio Biserna

2010 Hydromill

Floating hose-chain © Giovanni Casadei – Marco Pedrelli

2011 Tunnel

Rails on tunnel reverse arch © Alberto Navacchia

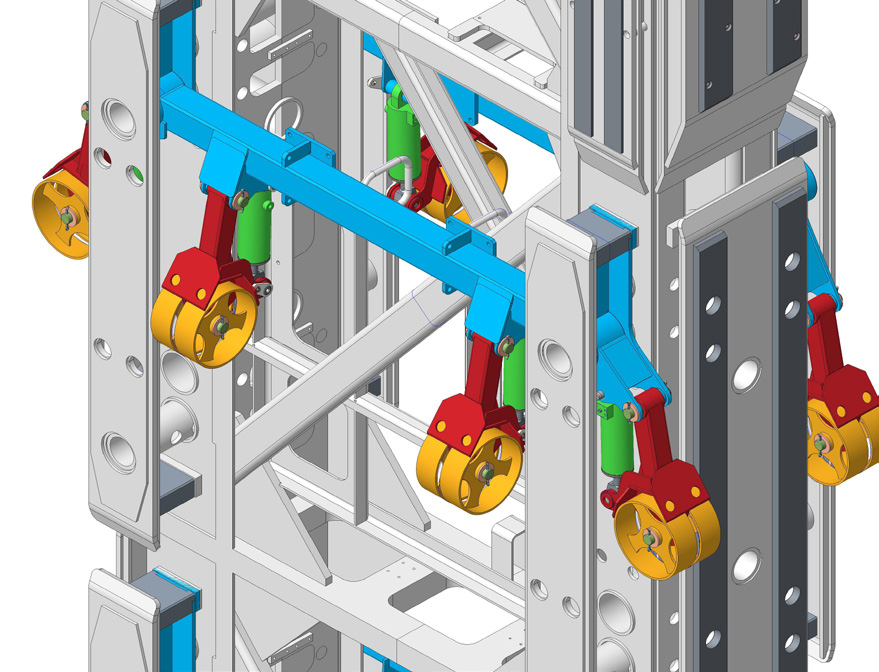

2011 Hydromill

Tensioned hose-chain © Giovanni Casadei

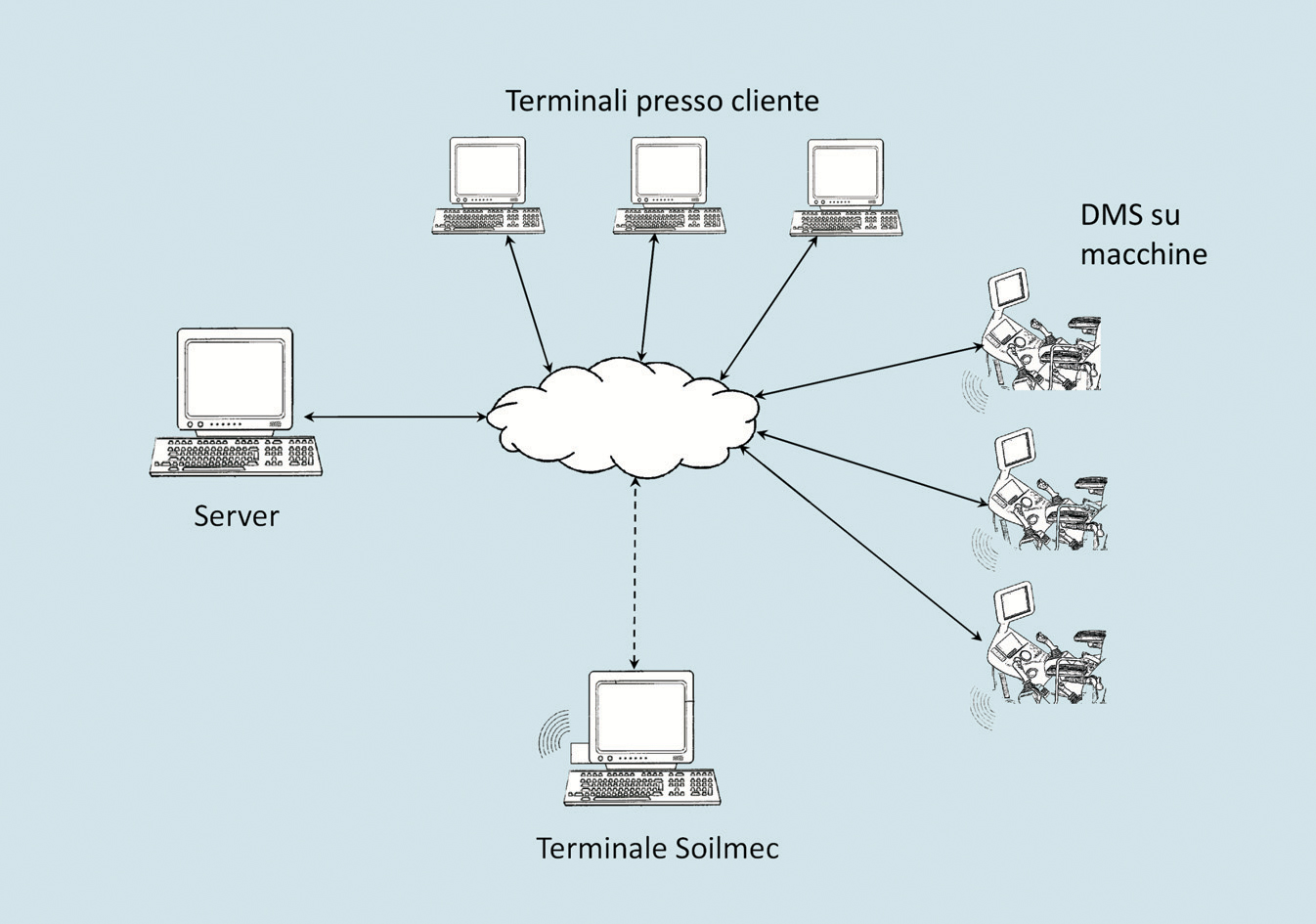

2011 DMS

DMS on cloud-computing © Ivano Guerra – Pietro Fontana

2011 DP

Axial displacement tool – Mazinga © Michelino Allegra – Terzo Turci – Rodolfo Accorsini

2011 Hydromill

Hooked hose-chain © Davide Trevisani

2011 Hydromill

Double winches and one rope motion © Giovanni Casadei

2011 Hydromill

Serial centrifugal pump for mud treatment plant © Davide Bagnoli

2011 Hydromill

Waterlift with light mud © Marco Pedrelli – Mirco Raffuzzi

2011 Jet Grouting

Sealing system and water lubrication © Mauro PiniVia Dismano, 5819

47522 Cesena (Forlì Cesena) Italy

Fax +39 0547 318548